- Home /

- Company En

About us

The Ciserom story begins in 1927 , when Gustav Bahner from Liechtenstein , a neighborhood of Oberlungwitz in East Germany establish a small sock factory called G.B.L.

-

Quality and experience of 90 years are the factor that differentiate Ciserom from competitors, in an aggressive competitive environment.

We succeeded this performance and we are proud of ,,The most promising Romanian brand” and other awards that certify our efforts.

Now the company has an annual production of 10 million pairs of socks and export 30% of these to Germany, Italy and France, with which has maintained lasting relationships since the years 60-70, but it has won new markets like Ireland, Switzerland, Spain, Greece, Austria, The Baltic States,UK and USA. Regarding the domestic market we have 2 stores in Sebes and we are present not only in textile stores and neighborhood stores, but especially in most large hypermarket networks (Carrefour, Selgros, Kaufland, Metro, Auchan, DM Drogerie, Romania Hypermarche, Hervis Sport) and we have developed an online store according to international trends.

Ciserom socks are manufactured to the highest quality standard with attention to details and care for buyer. Thanks to decades of experience , using the best raw material and also best technology, Ciserom is trying to attract a younger segment through stylistic choices, an increased attention paid to colored socks and thematic collections. A varied range of over 150 products for babies , children and adults, reaching over 2000 distinct landmarks, covers the most sophisticated socks taste.

-

In 1928 GBL took over the Romanian Textile Factories . The new factory is equipped with a variety of knitting machine for the production of silk socks, cotton or wool and underwear, For commissioning of the equipment were brought specialists from Oberlungwitz- Germany, the hometown of Gustav Bahner, a town that had an old tradition in the manufacture of socks knitting machines since 1731.

In 1944 the factory goes into the patrimony of the state and continue the production of socks and textile for Romania and for the export. Between 1946-1954, under sovietic administration the factory will be call TEBA (from the Banat Textila)name used only today by the oldest persons in the Sebes area. Then taken over as a Romanian state enterprise under the name ,, Fabrica de ciorapi si tricotaje Sebesul – Sebes socks and knitwear factory”. In period 1954-1987 our factory has modernized and specialized only on the production of socks reaching a capacity of 40 times higher, with 6 times more employees then at the beginning, reaching at 176.000 pairs of socks produced per day in 1989.

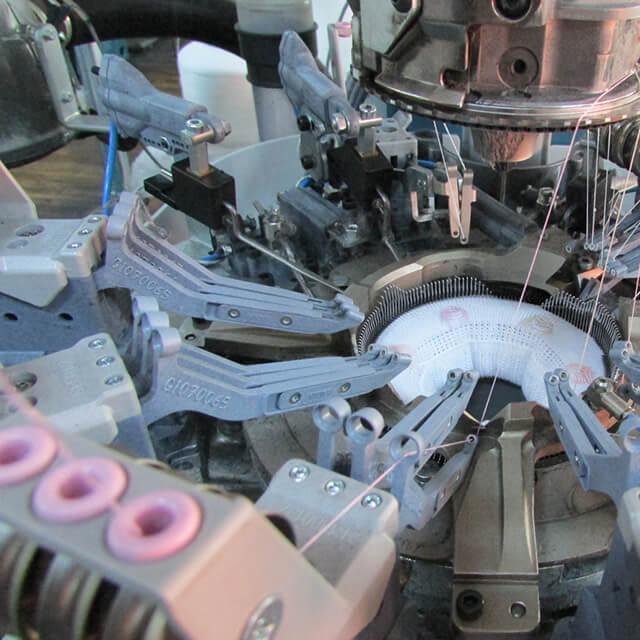

Ciserom Technology

Our strenght is the quality of the products resulting from an efficient technological process and performing machines , associated with a quality control over the entire production flow.

Today the company is tooled up with a series of equipment, such us:

- electronic knitting machines with one cylinder , gauge 14 E , with 108 to 168 needles

- new electronic knitting machines with one cylinder , gauge 14 E , with 156 and 168 needles

- electronic knitting machines with double cylinders , with 84 , 96 and 176 needles

- electronic knitting machines , 4" diameter , with 112 to 168 needles

- mechanical knitting machines with double cylinders , gauge 14 E , with 120 to 176 needles

- hand-linking machines

- linking machines type Rosso , with turnover device and without turnover device

- last generation boarding machines Tecnopea

- device for special treatment applied on socks with : silicone softener , aloe vera softener , antimicrobial and antibacterial products

- machines for shutting the socks in lots using plastic pins , in one side or on both sides

- machines for printing the variable information on labels

- sewing machines for labels with automatic label supplier and without it

- computers and scanners for scanning the labels code bares

Certifications

The system of quality management ISO 18001 / 2007 ensures the development of a sort of competences, among which:

- Creation of a working system with low risks for injuries and/or occupational illness.

- Achievement of a better control of risk factors for injury and/or occupational illness.

- Transparency and effectiveness in occupational health and safety management by translating the results of risk assessments, audits, inspections etc., in action plans to minimize the risks of accidents.

- Obtain of better performances for employees by providing “wellness” at work.

OEKO -TEX ® Standard 100 is an independent examination and certification system for textile products regarding the use of hazardous substances.

ISO 9001 is a certification program developed by The International Organization for Standardization, and it represents a strategy of management that improves the business relations of a company.

ISO 9001 involves the existence of a solid organizational structure to ensure the efficiency in production. The result consists in the increase of productivity and incomes and also fewer errors in production. Such performances help us to improve relations with suppliers and consumers but also to increase the staff’s morale through knowing the impact of individual activity on company, fact which leads to the increase of employee’s morale.

1927

1927Gustav Bahner establish the socks company in Sebes

1938

1938The company was extended under German leadership.

1944

1944The company pass in state patrimony.

1946

1946Under Russia's administration the company gets a new name: TEBA

1954

1954The company is under taken by Romanian state.

1974

1974Because of new technology production increase four times and the number of employers six times.

1990

1990The name of the company change into Ciserom

1995

1995The company was privatized.

2017

2017Ciserom celebrate 90 years of tradition in socks field.